Many importers use factory visits as an opportunity to strengthen their relationship with a supplier and evaluate their capabilities. Productive factory visits can lead to improved product quality, smoother communication, and fewer production delays. We consider checking our 3 factories as our main criteria for evaluating a supplier’s facility and capabilities.

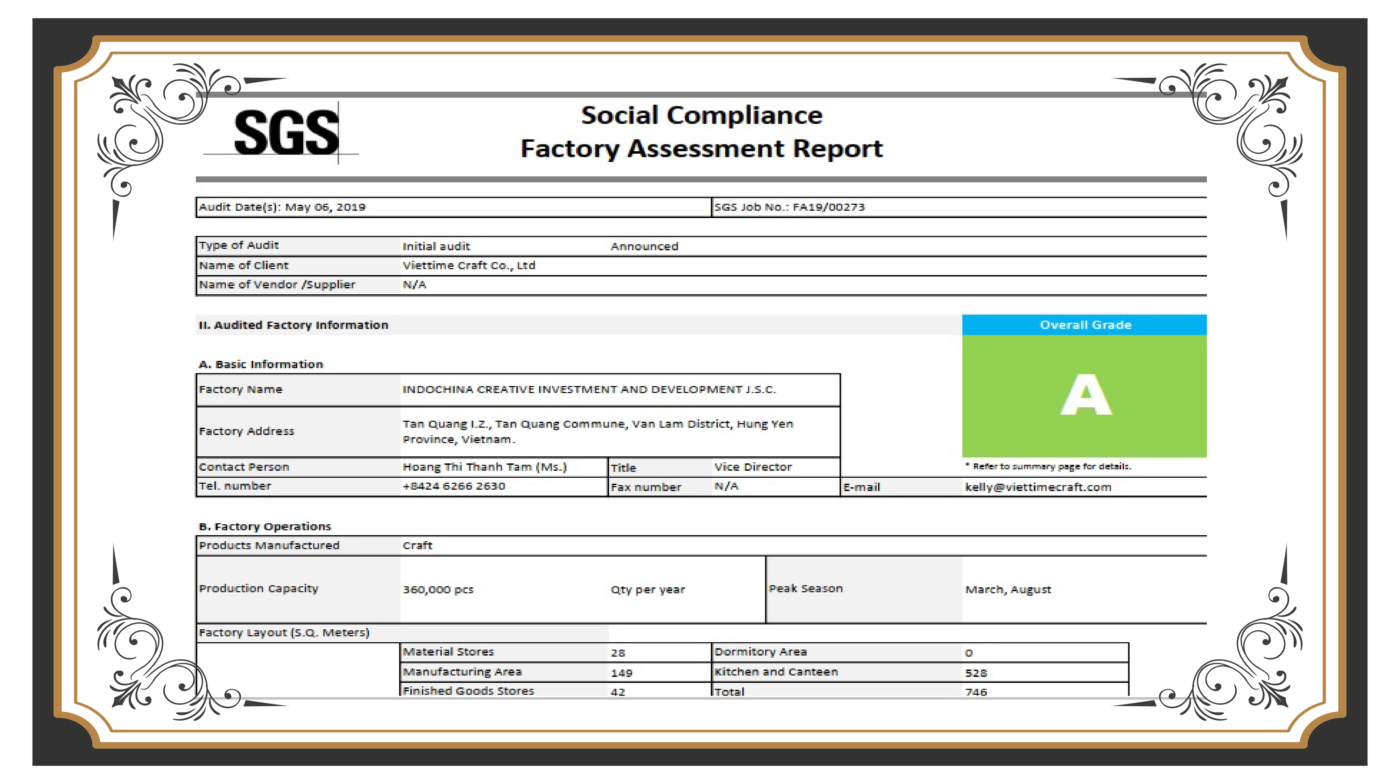

Manufacturing Audit

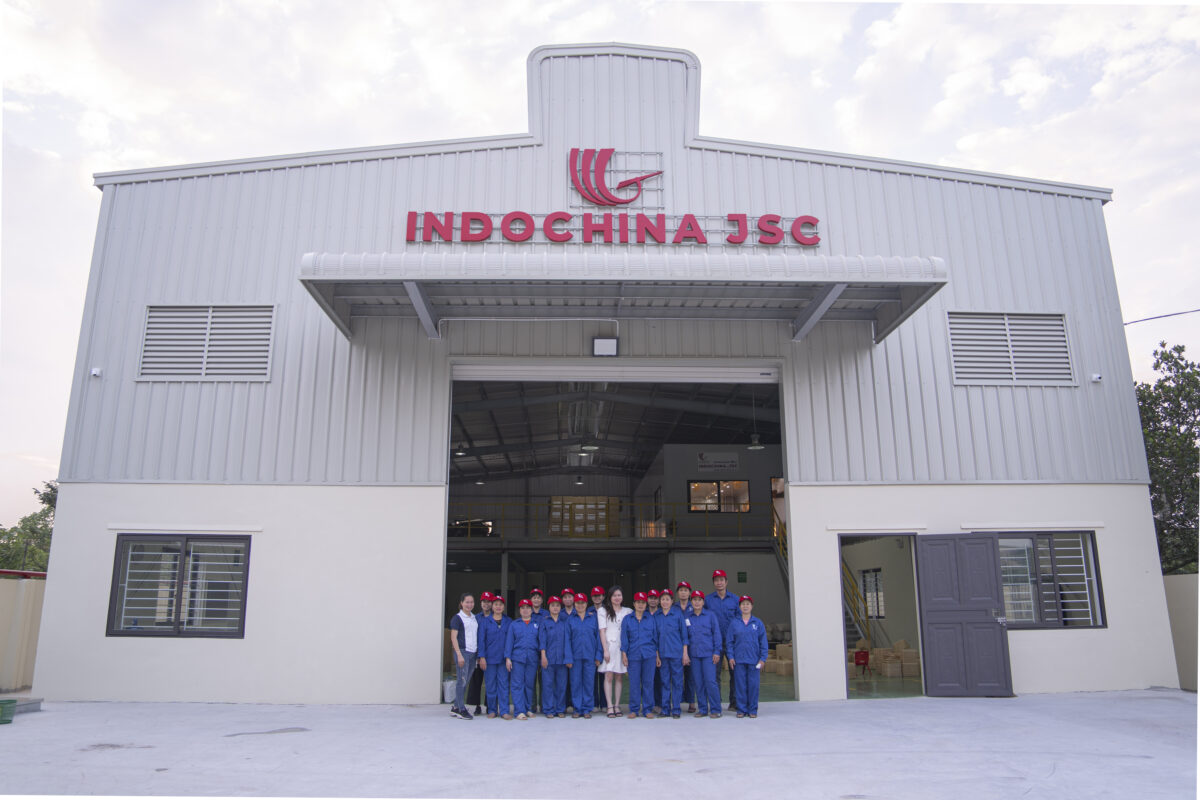

Viettimecraft has 3 factories in Ha Noi, Ninh Binh, and Hung Yen.

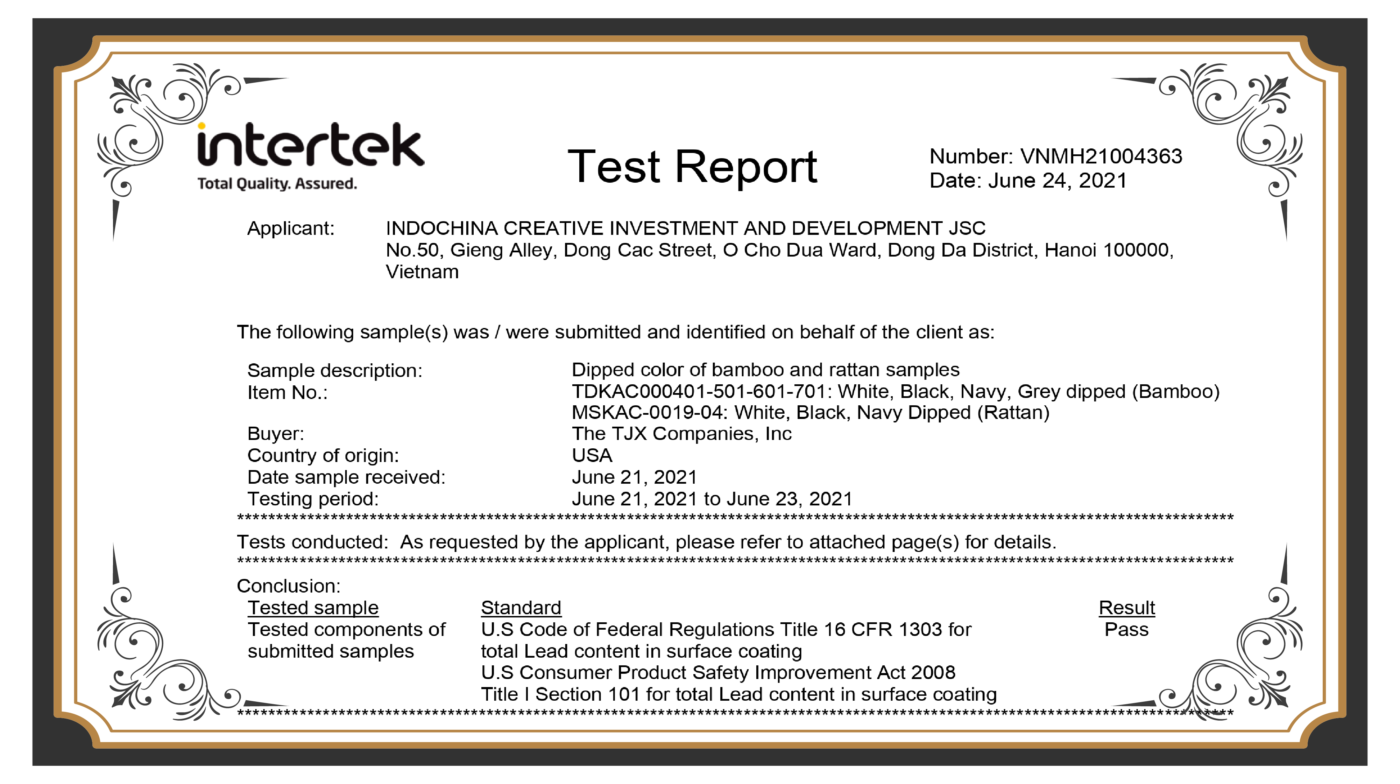

During a manufacturing factory audit, we meet all the regulations for producing a product that meets our company’s specifications, addresses costly disruptions, and prevents (further) costly disruptions. Moreover, verifies that our manufacturing facilities are suitable to produce our handicraft product. As a result, identifies and mitigates potential quality, operational, and ethical risks.

Viettimecraft knows the importance of investing in the cost of regularly maintaining equipment. Because tools or machines that aren’t maintained or recalibrated periodically can lead to product defects, non-conforming products, and inconsistent production runs. Our three factories ensure that we can operate and deliver bulk products on schedule.

Working Conditions and Instructions in our Factories

A social compliance audit is necessary to thoroughly assess our working conditions.

Our workers always wear the required protective gear to prevent injuries. Detailed work instructions are highly visible and clear, typically posted at each production station. They are relatively simple with visual examples included to illustrate procedures.

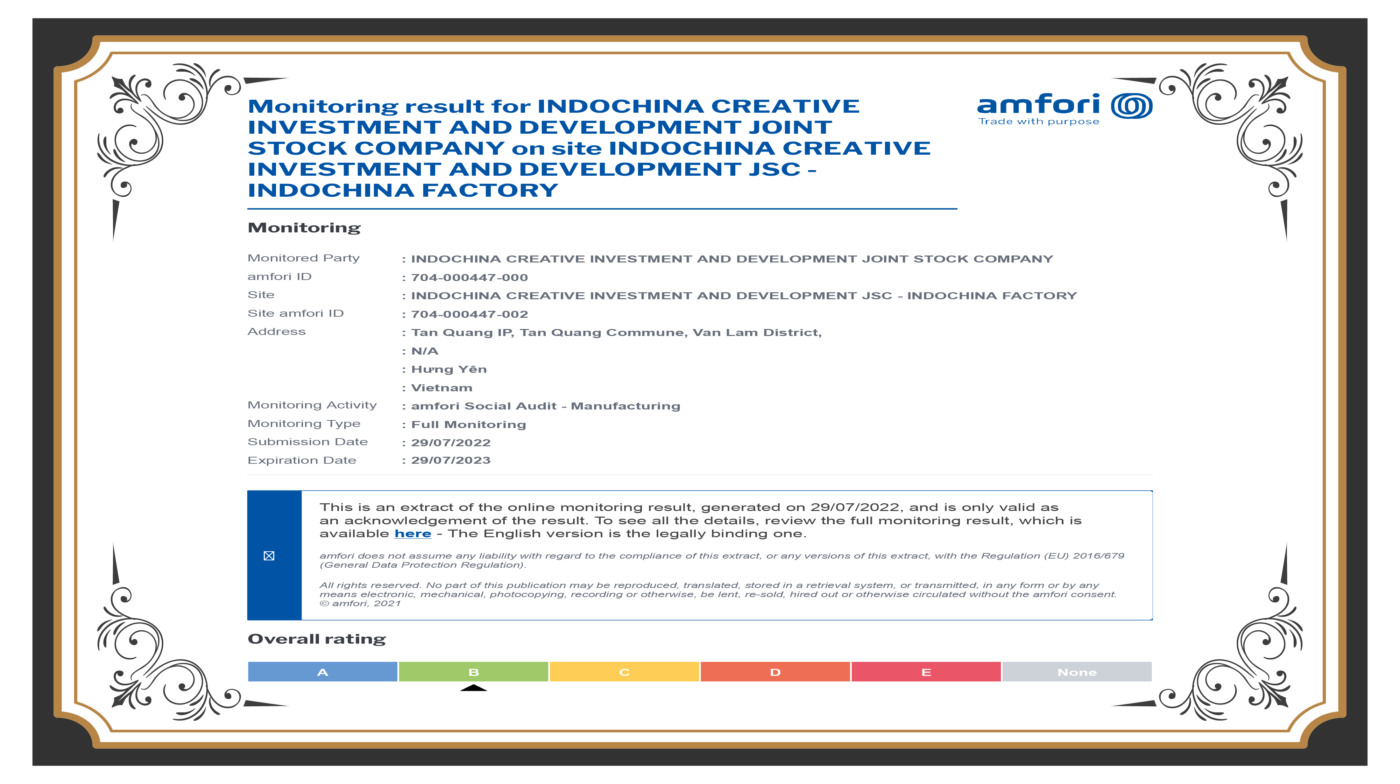

Ethical Audits

Ethical audits, BSCI for example, help to ensure social accountability is being reviewed. We provide healthy, safe, and ethical work environments, sound labor practices, and pay – an ethical audit ensures we follow the appropriate work conditions.

Our factories have decent working conditions and human rights practices. Ensures safe working conditions, which helps prevent minor and catastrophic injury, and employee health is not in danger.